Grain boundary diffusion (GBD) process to produce super-high grade neodymium magnet that traditional tech can’t. Such as 54SH,50UH,48EH,45AH and etc.

| Properties of GBD sintered NdFeB magnet |

| Series | Grade | Max Operating Temp. ℃ |

Remanence Br

mT(KG)

|

Coercivity Hcb

KA/m(KOe)

|

Intrinsic Coercivity Hcj

KA/m(KOe)

|

Maximium Energy Product

(BH)max KJ/m3 (MGOe)

|

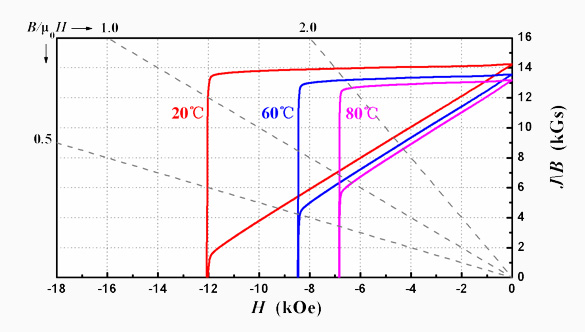

| SH | 50SH | ≤150℃ | 1400-1450(14.0-14.5) | ≥1003(≥12.6) | ≥1592(≥20) | 374-406(47-51) |

| 52SH | ≤150℃ | 1420-1460(14.2-14.6) | ≥1003(≥12.6) | ≥1592(≥20) | 392-422(49-53) | |

| 54SH | ≤150℃ | 1440-1490(14.4-14.9) | ≥1003(≥12.6) | ≥1592(≥20) | 398-430(50-54) | |

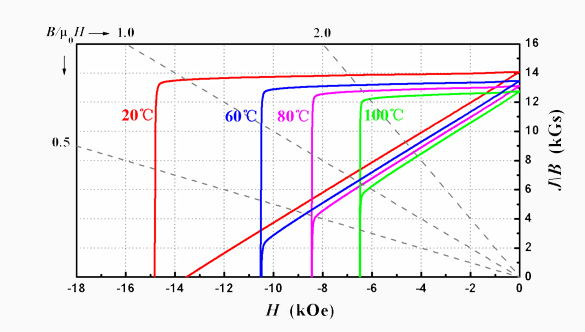

| UH | 48UH | ≤180℃ | 1370-1430(13.7-14.3) | ≥1011(≥12.7) | ≥1990(≥25) | 358-390(45-49) |

| 50UH | ≤180℃ | 1400-1450(14.0-14.5) | ≥1035(≥13.0) | ≥1990(≥25) | 374-406(47-51) | |

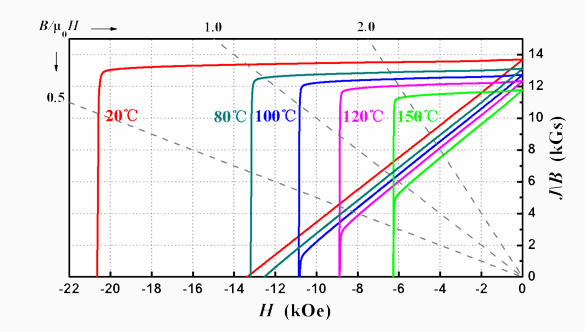

| EH | 42EH | ≤200℃ | 1280-1320(12.8-13.2) | ≥939(≥11.6) | ≥2388(≥30) | 320-340(38-41) |

| 45EH | ≤200℃ | 1320-1380(13.2-13.8) | ≥979(≥12.3) | ≥2388(≥30) | 342-366(43-46) | |

| 48EH | ≤200℃ | 1370-1430(13.7-14.3) | ≥979(≥12.3) | ≥2388(≥30) | 358-390(45-49) | |

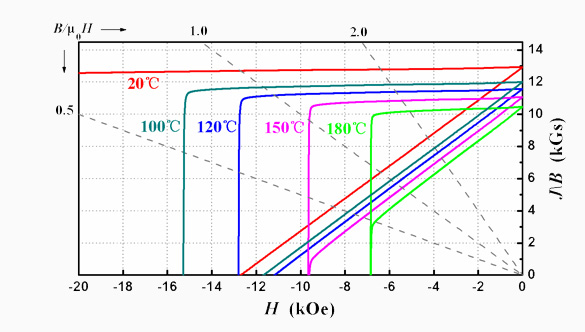

| AH | 40AH | ≤220℃ | 1250-1280(12.5-12.8) | ≥923(≥11.6) | ≥2624(≥33) | 302-326(38-41) |

| 42AH | ≤220℃ | 1280-1320(12.8-13.2) | ≥931(≥11.7) | ≥2624(≥33) | 318-342(40-43) | |

| 45AH | ≤220℃ | 1320-1380(13.2-13.8) | ≥932(≥11.7) | ≥2624(≥33) | 342-366(43-46) |

|

Features of grain boundary diffusion (GBD) |

1. GBD can produce super-high grade magnets that the traditional tech can't.

2. Greatly reduce the usage of Heavy Rare earth.

3. Increase Hcj sharply without much influence to Br.

4. Compare with traditional tech, it can greatly reduce dosage of heavy rare earth, and the cost of high Hcj magnets (SH - AH grade) will be changed accordingly.

5. It has limit to the dimensions of magnet. Please contact our sales engineer for the details.

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com