Linkup Magnet manufactures sintered neodymium magnet in custom sizes upon requirements.Our machining capabilities provide perfect solutions for both regular shapes and special shapes of sintered neodymium magnet,with good quality and maintain the price advantage.

| Available dimensions of arc sintered neodymium magnet |

Relying on experienced production team and strong maching capability,most sizes of neodymium magnet can be produced with very high quality,and the tolerance can be controlled within +/-0.05mm or +/-0.1mm.

|

Length | Width | Height | Wall Thickness | Angle |

| L ≦ 200 mm | W ≦ 100 mm | H ≦ 80 mm | T ≦ 80 mm | A ≦ 180° |

| How to choose the grade of sintered neodymium magnet |

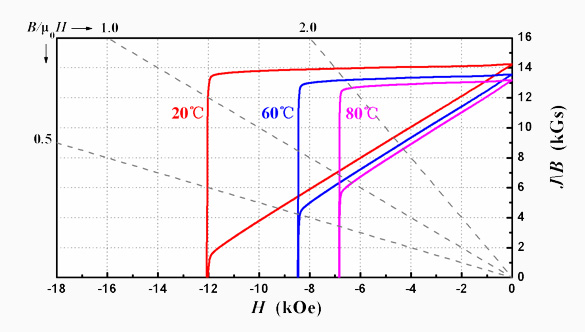

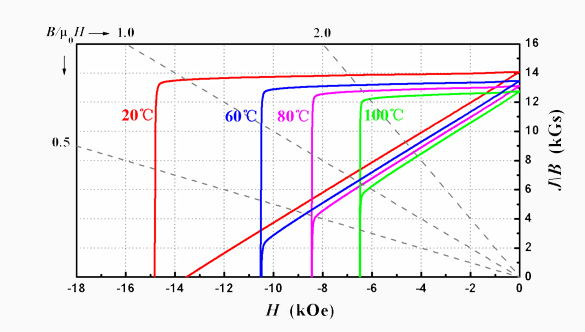

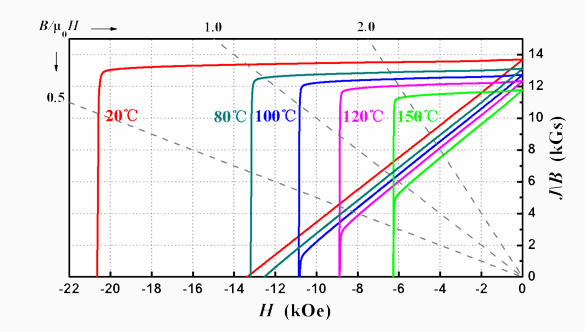

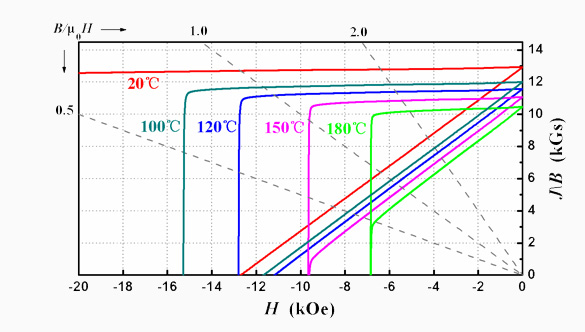

Basis on different temperature resistrance, the neodymium magnet are divided into N, M, H, SH, UH, EH, AH series, and the corresponding maximum operating temperature is 80℃, 100℃, 120℃, 150℃, 180℃, 200℃, 220℃.

In the same serires, the higher the grade of NdFeB magnet, the more magnetism it is. For example, in N series,N52 grade have more magnetic power than N35 grade, and the N55 grade is the strongest one.

For initial projects, we are happy to provide magnetic technology support and accept sample order according to your requirements for prototyping and testing needs.

Properties of sintered NdFeB magnet

| Series | Grade | Max Operating Temp. ℃ |

Remanence Br

mT(KG)

|

Coercivity Hcb

KA/m(KOe)

|

Intrinsic Coercivity Hcj

KA/m(KOe)

|

Maximium Energy Product

(BH)max KJ/m3 (MGOe)

|

| N | N35 | ≤80℃ |

1170-1220 (11.7-12.2) |

≥868(≥10.9) | ≥955(≥12) | 263-287(33-36) |

| N38 | ≤80℃ |

1220-1250 (12.2_12.5) |

≥899(≥11.3) | ≥955(≥12) | 287-310(36-39) | |

| N40 | ≤80℃ |

1250-1280 (12.5-12.8) |

≥907(≥11.4) | ≥955(≥12) | 302-326(38-41) | |

| N42 | ≤80℃ |

1280-1320 (12.8-13.2) |

≥915(≥11.5) | ≥955(≥12) | 318-342(40-43) | |

| N45 | ≤80℃ |

1320-1380 (13.2-13.8) |

≥923(≥11.6) | ≥955(≥12) | 342-366(43-46) | |

| N48 | ≤80℃ |

1380-1420 (13.8-14.2) |

≥923(≥11.6) | ≥955(≥12) | 366-390(46-49) | |

| N50 | ≤80℃ |

1400-1450 (14.0-14.5) |

≥836(≥10.5) | ≥955(≥12) | 382-406(48-51) | |

| N52 | ≤80℃ |

1430-1480 (14.3-14.8) |

≥836(≥10.5) | ≥876(≥11) | 398-422(50-53) | |

| N54 | ≤80℃ |

1450-1490 (14.5-14.9) |

≥836(≥10.5) | ≥876(≥11) | 406-438(51-55) | |

| N55 | ≤80℃ |

1470-1520 (14.7-15.2) |

≥836(≥10.5) | ≥876(≥11) | 414-438(52-56) | |

| M | 35M | ≤100℃ |

1170-1220 (11.7-12.2) |

≥868(≥10.9) | ≥1114(≥14) | 263-287(33-36) |

| 38M | ≤100℃ |

1220-1250 (12.2-12.5) |

≥899(≥11.3) | ≥1114(≥14) | 287-310(36-39) | |

| 40M | ≤100℃ |

1250-1280 (12.5-12.8) |

≥923(≥11.6) | ≥1114(≥14) | 302-326(38-40) | |

| 42M | ≤100℃ |

1280-1320 (12.8-13.2) |

≥955(≥12.0) | ≥1114(≥14) | 318-342(40-43) | |

| 45M | ≤100℃ |

1320-1380 (13.2-13.8) |

≥955(≥12.5) | ≥1114(≥14) | 342-366(43-46) | |

| 48M | ≤100℃ |

1360-1430 (13.6-14.3) |

≥1027(≥12.9) | ≥1114(≥14) | 366-390(46-49) | |

| 50M | ≤100℃ |

1400-1450 (14.0-14.5) |

≥1033(≥13.0) | ≥1114(≥14) | 382-406(48-51) | |

| 52M | ≤100℃ |

1420-1460 (14.2-14.6) |

≥1033(≥13.0) | ≥1114(≥14) | 398-414(50-52) | |

| 54M | ≤100℃ |

1450-1490 (14.5-14.9) |

≥1051(≥13.2) | ≥1114(≥14) | 406-438(51-55) | |

| H | 35H | ≤120℃ |

1170-1220 (11.7-12.2) |

≥868(≥10.9) | ≥1353(≥17) | 263-287(33-36) |

| 38H | ≤120℃ |

1220-1250 (12.2-12.5) |

≥899(≥11.3) | ≥1353(≥17) | 287-310(36-39) | |

| 40H | ≤120℃ |

1250-1280 (12.5-12.8) |

≥923(≥11.6) | ≥1353(≥17) | 302-326(38-41) | |

| 42H | ≤120℃ |

1280-1320 (12.8-13.2) |

≥955(≥12.0) | ≥1353(≥17) | 318-342(40-43) | |

| 45H | ≤120℃ |

1300-1360 (13.0-13.6) |

≥963(≥12.1) | ≥1353(≥17) | 326-358(43-46) | |

| 48H | ≤120℃ |

1370-1430 (13.7-14.3) |

≥955(≥12.5) | ≥1353(≥17) | 366-390(46-49) | |

| 50H | ≤120℃ |

1400-1450 (14.0-14.5) |

≥955(≥12.5) | ≥1353(≥17) | 382-406(48-51) | |

| 52H | ≤120℃ |

1420-1460 (14.2-14.6) |

≥1043(≥13.1) | ≥1353(≥17) | 390-422(49-53) | |

| 54H | ≤120℃ |

1440-1490 (14.4-14.9) |

≥1043(≥13.1) | ≥1353(≥17) | 398-438(50-55) | |

| SH | 35SH | ≤150℃ |

1170-1220 (11.7-12.2) |

≥876(≥11.0) | ≥1592(≥20) | 263-287(33-36) |

| 38SH | ≤150℃ |

1220-1250 (12.2-12.5) |

≥907(≥11.4) | ≥1592(≥20) | 287-310(36-39) | |

| 40SH | ≤150℃ |

1240-1280 (12.5-12.8) |

≥939(≥11.8) | ≥1592(≥20) | 302-326(38-41) | |

| 42SH | ≤150℃ |

1280-1320 (12.8-13.2) |

≥987(≥12.4) | ≥1592(≥20) | 318-342(40-43) | |

| 45SH | ≤150℃ |

1320-1380 (13.2-13.8) |

≥1003(≥12.6) | ≥1592(≥20) | 342-366(43-46) | |

| 48SH | ≤150℃ |

1370-1430 (13.7-14.3) |

≥1011(≥12.7) | ≥1592(≥20) | 358-390(45-49) | |

| 50SH | ≤150℃ |

1400-1450 (14.0-14.5) |

≥1003(≥12.6) | ≥1592(≥20) | 374-406(47-51) | |

| 52SH | ≤150℃ |

1420-1460 (14.2-14.6) |

≥1003(≥12.6) | ≥1592(≥20) | 392-422(49-53) | |

| 54SH | ≤150℃ |

1440-1490 (14.4-14.9) |

≥1003(≥12.6) | ≥1592(≥20) | 398-430(50-54) | |

| UH | 30UH | ≤180℃ |

1080-1130 (10.8-11.3) |

≥812(≥10.2) | ≥1990(≥25) | 223-247(28-31) |

| 33UH | ≤180℃ |

1130-1170 (11.3-11.7) |

≥852(≥10.7) | ≥1990(≥25) | 247-271(31-34) | |

| 35UH | ≤180℃ |

1180-1220 (11.8-12.2) |

≥860(≥10.8) | ≥1990(≥25) | 263-287(33-36) | |

| 38UH | ≤180℃ |

1220-1250 (12.2-12.5) |

≥876(≥11.0) | ≥1990(≥25) | 287-310(36-39) | |

| 40UH | ≤180℃ |

1240-1280 (12.4-12.8) |

≥899(≥11.3) | ≥1990(≥25) | 302-326(38-41) | |

| 42UH | ≤180℃ |

1280-1320 (12.8-13.2) |

≥899(≥11.3) | ≥1990(≥25) | 318-342(40-43) | |

| 45UH | ≤180℃ |

1320-1380 (13.2-13.8) |

≥899(≥11.3) | ≥1990(≥25) | 334-358(42-45) | |

| 48UH | ≤180℃ |

1370-1430 (13.7-14.3) |

≥1011(≥12.7) | ≥1990(≥25) | 358-390(45-49) | |

| 50UH | ≤180℃ |

1400-1450 (14.0-14.5) |

≥1035(≥13.0) | ≥1990(≥25) | 374-406(47-51) | |

| EH | 28EH | ≤200℃ |

1040-1090 (10.4-10.9) |

≥780(≥9.8) | ≥2388(≥30) | 207-231(26-29) |

| 30EH | ≤200℃ |

1080-1130 (10.8-11.3) |

≥812(≥10.2) | ≥2388(≥30) | 223-247(28-31) | |

| 33EH | ≤200℃ |

1130-1170 (11.3-11.7) |

≥836(≥10.5) | ≥2388(≥30) | 247-271(31-34) | |

| 35EH | ≤200℃ |

1170-1220 (11.7-12.2) |

≥876(≥11.0) | ≥2388(≥30) | 263-287(33-36) | |

| 38EH | ≤200℃ |

1220-1250 (12.2-12.5) |

≥899(≥11.3) | ≥2388(≥30) | 287-310(36-39) | |

| 40EH | ≤200℃ |

1240-1280 (12.4-12.8) |

≥939(≥11.6) | ≥2388(≥30) | 302-326(38-41) | |

| 42EH | ≤200℃ |

1280-1320 (12.8-13.2) |

≥939(≥11.6) | ≥2388(≥30) | 320-340(38-41) | |

| 45EH | ≤200℃ |

1320-1380 (13.2-13.8) |

≥979(≥12.3) | ≥2388(≥30) | 342-366(43-46) | |

| 48EH | ≤200℃ |

1370-1430 (13.7-14.3) |

≥979(≥12.3) | ≥2388(≥30) | 358-390(45-49) | |

| AH | 30AH | ≤220℃ |

1020-1080 (10.2-10.8) |

≥804(≥10.1) | ≥2624(≥33) | 223-239(28-30) |

| 33AH | ≤220℃ |

1140-1170 (11.4-11.7) |

≥844(≥10.6) | ≥2624(≥33) | 247-263(31-33) | |

| 35AH | ≤220℃ |

1170-1210 (11.7-12.1) |

≥876(≥10.9) | ≥2624(≥33) | 263-279(33-36) | |

| 38AH | ≤220℃ |

1220-1250 (12.2-12.5) |

≥876(≥10.9) | ≥2624(≥33) | 279-310(36-39) | |

| 40AH | ≤220℃ |

1250-1280 (12.5-12.8) |

≥923(≥11.6) | ≥2624(≥33) | 302-326(38-41) | |

| 42AH | ≤220℃ |

1280-1320 (12.8-13.2) |

≥931(≥11.7) | ≥2624(≥33) | 318-342(40-43) | |

| 45AH | ≤220℃ |

1320-1380 (13.2-13.8) |

≥932(≥11.7) | ≥2624(≥33) | 342-366(43-46) |

|

Download PDF file of properties of Sintered NdFeB magnet |

|

Note: |

|

1. The above mentioned data of magnetic parameters and physical properties are given at room temperature. |

|

2. GBD process magnet for 54SH, 50UH, 48EH, 45AH,required thickness of magnet less than 5 mm. |

| 3. GBD process magnet for 52SH, 50SH, 48UH, 45Uh, 45EH, 42EH, 42AH, 40AH, required thickness of magnet less than 8 mm. |

| Available coating of sintered NdFeB magnet |

For general use,zinc and nickel plating are most common,and the salt spray test can reach 24 hours to 48 hours. Epoxy or NiCu+Epoxy Coating have a better corrosion resistance,the salt spray test can reach 72 hours.

| Coating | Thickness | Clor | SST | Characteristic |

| Cr3+Zn | 4-8 μm | Bright Blue | >24H~48H | Regular Protection,Applicable to most products |

| Colored Zn | 4-8 μm | Shining Color | >48H~72H | Excellent salt spray resistance |

| NiCuNi | 10-20 μm | Bright Silver | >24H~72H | Excellent humidity,heat & salt spray resistance,High temperature resistance. |

| NiCuNi+Cr | 10-25 μm | Bright Silver | >48H~72H | |

| NiCuNi+Sn | 10-25 μm | Silver | >48H~72H | |

| Electroless Nickel | 4-8 μm | Silver | >92H | |

| Phosphating +Epoxy | 10-20 μm | Black or Gray | >168H | Excellent humidity,heat & salt spray resistance;Excellent adhesion;Excellent Insulation |

| NiCu+Epoxy | 10-20 μm | Black or Gray | >168H | Excellent humidity,heat & salt spray resistance;Excellent adhesion;Excellent Insulation |

| Sprayed Epoxy | 10-30 μm | Black or Gray | >72H | Excellent humidity,heat & salt spray resistance;Excellent Insulation |

| Phosphated/Passivation | 1-3 μm | Dark Grey | <2.5H | Temporary Protection |

| Everlube | 8-20 μm | Yellow | >24H | Excellent Ssalt spray resistance |

| Teflon | >10 μm | Black or Blue | >16H | Excellent fricction resistance; High/low temp resistance;Anti-corrosion; Acid and alkali resistant; |

| NiCuNi+Au | 10-15 μm | Golden | >12H | Good looking |

| Parylene | 6-12 μm | Transparent | >24H | Good electrical insulation; Moisture-proof; Anti-corrosion and anti salt spray are excellent; |

|

|

|

|

NiCUNi

|

Cr3+Zn

|

Black Epoxy

|

|

|

|

|

NiCuNi+Au

|

NiCuNi+Cr

|

Everlube

|

|

|

|

|

Phosphated |

Teflon |

| Magnetization direction of arc sintered neodymium magnet |

Arc neodymium magnet can be diametrical magnetized in pair,magnetized through thickness or width.

|

|

|

| Diametrical Magnetized (S-N) |

Diametrical Magnetized (N-S) |

Magnetized Through Thickness |

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com