Sintered NdFeB magnets greatly expand the applications of permanent magnets.They are widely used in the fields of transportation,energy,communications,home appliances,machinery and medical equipment and have become indispensible function materials in manufacturing and daily life.

Linkup Magnet manufactures sintered neodymium magnet in custom sizes upon requirements.Our machining capabilities provide perfect solutions for both regular shapes and special shapes of NdFeB magnet,with good quality and maintain the price advantage.

What sizes of countersunk NdFeB magnet are available?

Relying on experienced production team and strong maching capability,most sizes of neodymium magnet can be produced with very high quality,and the tolerance can be controlled within +/-0.05mm or +/-0.1mm.

Please see below available sizes of round countersunk neodymium magnet

| Magnetization Orientation | Diameter | Thickness |

| Axial Mangetized | OD ≦ 240mm | 3 ≦ T ≦ 80mm |

The countersunk holes can meet M3,M4,M5,M6,M8,M10 and other screws or according to your requirements. No matter the shape of neodymium magnet is block,arc or irregular,with our advanced drilling equipment,countersunk holes or straight holes can be done well.

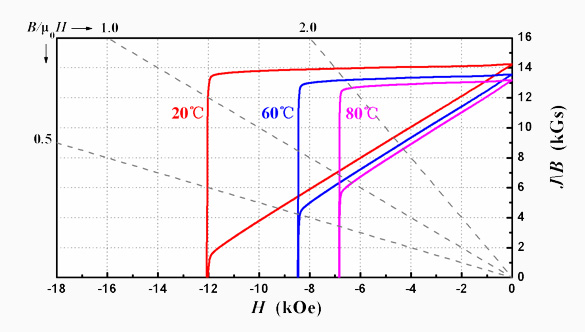

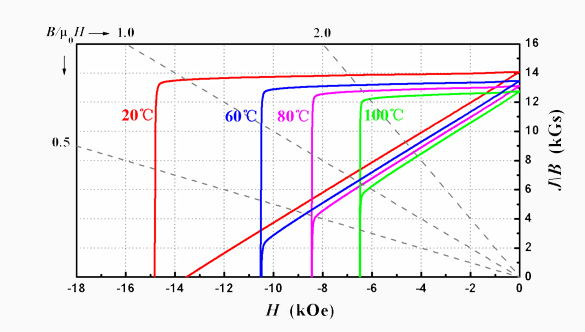

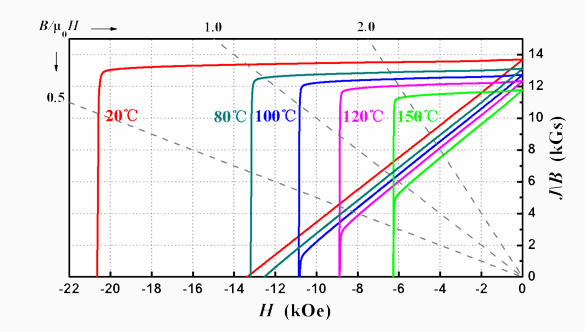

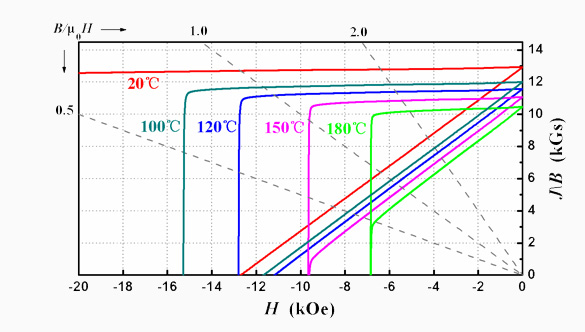

Different grade of sintered neodymium magnet

Basis on different temperature resistrance,the neodymium magnet are divided into N,M,H,SH,UH,EH,AH series,and the corresponding maximum operating temperature is 80℃,100℃,120℃,150℃,180℃,200℃,220℃.

In the same serires,the higher the grade of NdFeB magnet,the more magnetism it is.For example,in N series,N52 grade have more magnetic power than N35 grade,and the N55 grade is the strongest one.

For initial projects,we are happy to provide magnetic technology support and made magnet samples according to your requirements for prototyping or testing needs.

Check the grade/properities of sintered neodymium magnet.

Surface treatment of sintered neodymium Magnet

For general use,zinc and nickel plating are most common,and the salt spray test can reach 24 hours to 48 hours.

Epoxy or NiCu+Epoxy Coating have a better corrosion resistance,the salt spray test can reach 72 hours.

| Coating Type | Thickness | Clors | Resistance | ||

| PCT/HAST | SST | Temp.& Humi. | |||

| Zn (White Zn) | ≥5 μm | Bright Blue | —— | ★★ | ★★★ |

| Zn (Color-plated Zn) | ≥5 μm | Shining Color | —— | ★★★ | ★★★★ |

| Ni+Cu+N | ≥15 μm | Silver | ★★★ | ★★★★ | ★★★★★ |

| Ni+Cu+Ni+Cr | ≥15 μm | Silver | ★★★★ | ★★★★ | ★★★★★ |

| Ni+Cu+Ni+Sn | ≥15 μm | Silver | ★★★★ | ★★★★ | ★★★★★ |

| Chemic Ni | ≥5 μm | Silver | ★★★★ | ★★★★★ | ★★★★★ |

| Epoxy | ≥12 μm | Black | ★★★ | ★★★★★ | ★★★★★ |

| NiCu+Epoxy | ≥15 μm | Black | ★★★ | ★★★★★ | ★★★★★ |

| Passivated | ≤2 μm | Silver Grey | —— | —— | ★★★ |

| Phosphated | ≤2 μm | Silver Grey | —— | —— | ★★★ |

Magnetization orientation of countersunk neodymium magnet

Most of countersunk neodymium magnet are axial magnetized,and them can be magnetized in a pair,one piece S pole on countersunk hole surface,and the other one N pole on countersunk hole surface.This way, after they are fixed, the countersunk surface can be perfectly sucked together.

|

|

| Axial Magnetized (S-N) | Axial Magnetized (N-S) |

| Similar Products Show |

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com