Sintered NdFeB magnets greatly expand the applications of permanent magnets.They are widely used in the fields of transportation,energy,communications,home appliances,machinery and medical equipment and have become indispensible function materials in manufacturing and daily life.

Linkup Magnet manufactures sintered neodymium magnet in custom sizes upon requirements.Our machining capabilities provide perfect solutions for both regular shapes and special shapes of NdFeB magnet,with good quality and maintain the price advantage.

What size of NdFeB magnet with adhesive are available?

Relying on experienced production team and strong maching capability,most sizes of neodymium magnet can be produced with very high quality,and the tolerance can be controlled within +/-0.05mm or +/-0.1mm.

Round/disc neodymium magnet

Magnetization Orientation

Diameter

Thickness

Axial Mangetized

OD ≦ 240mm

T ≦ 80mm

Diametrical Magnetized

OD ≦ 80mm

T ≦ 60mm

Block neodymium magnet.

| Length | Width | Thickness |

| 1mm ≦ L ≦ 240mm | 1mm ≦ L ≦ 100mm | 1mm ≦ L ≦ 80mm |

What grade of neodymium magnet you may need?

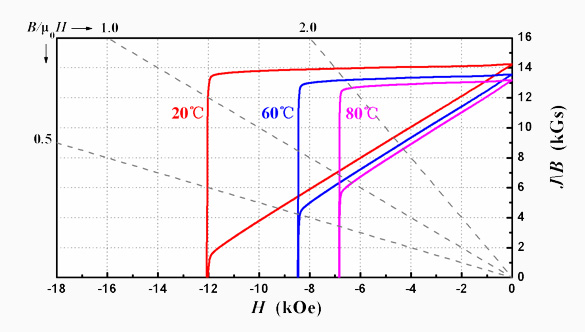

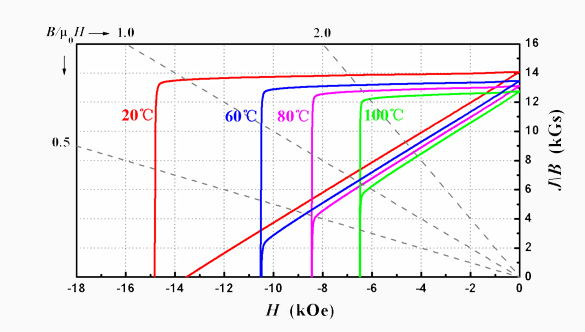

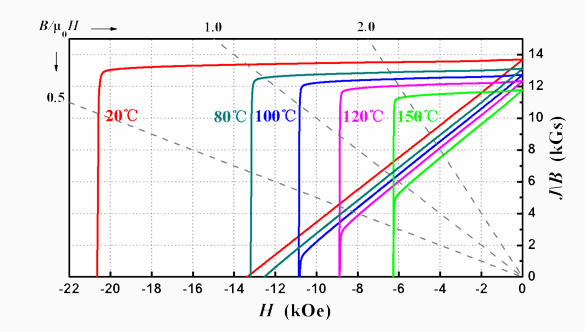

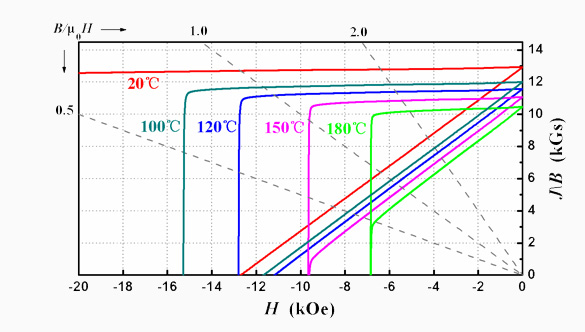

Basis on different temperature resistrance,the neodymium magnet are divided into N,M,H,SH,UH,EH,AH series,and the corresponding maximum operating temperature is 80℃,100℃,120℃,150℃,180℃,200℃,220℃.

In the same serires,the higher the grade of NdFeB magnet,the more magnetism it is.For example,in N series,N52 grade have more magnetic power than N35 grade,and the N55 grade is the strongest one.

For initial projects,we are happy to provide magnetic technology support and made magnet samples according to your requirements for prototyping or testing needs.

Check the grade/properities of sintered neodymium magnet.

How about the corrosion resistance of the coating?

The salt spray test is the best way to evaluate the quality of coating.For general use,zinc and nickel plating are the most common,and the salt spray test can reach 24 hours to 48 hours.If the magnet is to be used in a wet environment,NiCu+Epoxy Coating is recommended,the salt spray test can reach 72 hours.

| Coating Type | Thickness | Clors | Resistance | ||

| PCT/HAST | SST | Temp.& Humi. | |||

| Zn (White Zn) | ≥5 μm | Bright Blue | —— | ★★ | ★★★ |

| Zn (Color-plated Zn) | ≥5 μm | Shining Color | —— | ★★★ | ★★★★ |

| Ni+Cu+N | ≥15 μm | Silver | ★★★ | ★★★★ | ★★★★★ |

| Ni+Cu+Ni+Cr | ≥15 μm | Silver | ★★★★ | ★★★★ | ★★★★★ |

| Ni+Cu+Ni+Sn | ≥15 μm | Silver | ★★★★ | ★★★★ | ★★★★★ |

| Chemic Ni | ≥5 μm | Silver | ★★★★ | ★★★★★ | ★★★★★ |

| Epoxy | ≥12 μm | Black | ★★★ | ★★★★★ | ★★★★★ |

| NiCu+Epoxy | ≥15 μm | Black | ★★★ | ★★★★★ | ★★★★★ |

| Passivated | ≤2 μm | Silver Grey | —— | —— | ★★★ |

| Phosphated | ≤2 μm | Silver Grey | —— | —— | ★★★ |

Magnetization orientation of round/disc neodymium magnet.

Most of round/disc neodymium magnet are axial magnetized.But there are some application that require magnetization of its diametrical direction.Adhesive neodymium magnet can be attached with 3M adhesive or Chinese adhesive,normal adhesive or foam tape.

|

|

|

Axial Magnetized With Normal Adhesive (3M or Chinese adhesive) |

Diametrical Magnetized With Normal Adhesive (3M or Chinese adhesive) |

|

|

|

Axial Magnetized With Foam Tape |

Diametrical Magnetized With Foam Tape |

| Products Show |

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com